Robotics

Robotics is an interdisciplinary field that involves the design, construction, operation, and use of robots.

Robotics integrates many fields that deal with specific aspects of robotics. For example, within mechanical engineering, the term robotics refers to the construction of the physical structures of a robots, while in computer science, robotics focuses on the study of robotic software.

There are also many other aspects of robotic development and related fields that overleap in its, including electrical, control, software, information, electronic, telecommunication, computer, mechatronic, materials and biomedical engineering. The goal of robotics is to design machines that can help and assist humans.

The field of robotics develops machines that can automate tasks and do various jobs that a human might not be able to do. Robots can be used in many situations for many purposes, but today many are used in dangerous environments (including inspection of radioactive materials, bomb detection and deactivation), manufacturing processes, or where humans cannot survive (e.g., in space, underwater, in high heat, and clean up and containment of hazardous materials and radiation).

Robots can take any form, but some are made to resemble humans in appearance. This is claimed to help in the acceptance of robots in certain replicative behaviors that are usually performed by people. Such robots attempt to replicate walking, lifting, speech, cognition, or any other tasks mainly performed by a human. Many of today’s robots are inspired by nature, contributing to the field of bio-inspired robotics.

The field of robotics develops machines that can automate tasks and do various jobs that a human might not be able to do. Robots can be used in many situations for many purposes, but today many are used in dangerous environments (including inspection of radioactive materials, bomb detection and deactivation), manufacturing processes, or where humans cannot survive (e.g., in space, underwater, in high heat, and clean up and containment of hazardous materials and radiation).

Robots can take any form, but some are made to resemble humans in appearance. This is claimed to help in the acceptance of robots in certain replicative behaviors that are usually performed by people. Such robots attempt to replicate walking, lifting, speech, cognition, or any other tasks mainly performed by a human. Many of today’s robots are inspired by nature, contributing to the field of bio-inspired robotics.

Robotic aspects

There are many types of robots; they are used in many different environments and for many different uses. Although being very diverse in application and form, they all share three basic similarities when it comes to their construction:

Robots all have some kind of mechanical construction, a frame, form or shape designed to achieve a particular task. For example, a robot designed to travel across heavy dirt or mud might use caterpillar tracks. Origami inspired robots can sense and analyze in extreme environments. The mechanical aspect of the robot is mostly the creator’s solution to completing the assigned task and dealing with the physics of the environment around it. Form follows function.

Robots have electrical components that power and control the machinery. For example, the robot with caterpillar tracks would need some kind of power to move the tracker treads. That power comes in the form of electricity, which will have to travel through a wire and originate from a battery, a basic electrical circuit.

Robots all have some kind of mechanical construction, a frame, form or shape designed to achieve a particular task. For example, a robot designed to travel across heavy dirt or mud might use caterpillar tracks. Origami inspired robots can sense and analyze in extreme environments. The mechanical aspect of the robot is mostly the creator’s solution to completing the assigned task and dealing with the physics of the environment around it. Form follows function.

Robots have electrical components that power and control the machinery. For example, the robot with caterpillar tracks would need some kind of power to move the tracker treads. That power comes in the form of electricity, which will have to travel through a wire and originate from a battery, a basic electrical circuit.

Even petrol-powered machines that get their power mainly from petrol still require an electric current to start the combustion process which is why most petrol-powered machines like cars, have batteries. The electrical aspect of robots is used for movement (through motors), sensing (where electrical signals are used to measure things like heat, sound, position, and energy status), and operation (robots need some level of electrical energy supplied to their motors and sensors in order to activate and perform basic operations)

All robots contain some level of computer programming code. A program is how a robot decides when or how to do something. In the caterpillar track example, a robot that needs to move across a muddy road may have the correct mechanical construction and receive the correct amount of power from its battery, but would not be able to go anywhere without a program telling it to move.

Even petrol-powered machines that get their power mainly from petrol still require an electric current to start the combustion process which is why most petrol-powered machines like cars, have batteries. The electrical aspect of robots is used for movement (through motors), sensing (where electrical signals are used to measure things like heat, sound, position, and energy status), and operation (robots need some level of electrical energy supplied to their motors and sensors in order to activate and perform basic operations)

All robots contain some level of computer programming code. A program is how a robot decides when or how to do something. In the caterpillar track example, a robot that needs to move across a muddy road may have the correct mechanical construction and receive the correct amount of power from its battery, but would not be able to go anywhere without a program telling it to move.

Programs are the core essence of a robot, it could have excellent mechanical and electrical construction, but if its program is poorly structured, its performance will be very poor (or it may not perform at all). There are three different types of robotic programs: remote control, artificial intelligence, and hybrid. A robot with remote control programming has a preexisting set of commands that it will only perform if and when it receives a signal from a control source, typically a human being with remote control. It is perhaps more appropriate to view devices controlled primarily by human commands as falling in the discipline of automation rather than robotics.

Robots that use artificial intelligence interact with their environment on their own without a control source, and can determine reactions to objects and problems they encounter using their preexisting programming. A hybrid is a form of programming that incorporates both AI and RC functions in them.

Programs are the core essence of a robot, it could have excellent mechanical and electrical construction, but if its program is poorly structured, its performance will be very poor (or it may not perform at all). There are three different types of robotic programs: remote control, artificial intelligence, and hybrid. A robot with remote control programming has a preexisting set of commands that it will only perform if and when it receives a signal from a control source, typically a human being with remote control. It is perhaps more appropriate to view devices controlled primarily by human commands as falling in the discipline of automation rather than robotics.

Robots that use artificial intelligence interact with their environment on their own without a control source, and can determine reactions to objects and problems they encounter using their preexisting programming. A hybrid is a form of programming that incorporates both AI and RC functions in them.

Robots all have some kind of mechanical construction, a frame, form or shape designed to achieve a particular task. For example, a robot designed to travel across heavy dirt or mud might use caterpillar tracks. Origami inspired robots can sense and analyze in extreme environments. The mechanical aspect of the robot is mostly the creator’s solution to completing the assigned task and dealing with the physics of the environment around it. Form follows function.

Robots have electrical components that power and control the machinery. For example, the robot with caterpillar tracks would need some kind of power to move the tracker treads. That power comes in the form of electricity, which will have to travel through a wire and originate from a battery, a basic electrical circuit.

Robots all have some kind of mechanical construction, a frame, form or shape designed to achieve a particular task. For example, a robot designed to travel across heavy dirt or mud might use caterpillar tracks. Origami inspired robots can sense and analyze in extreme environments. The mechanical aspect of the robot is mostly the creator’s solution to completing the assigned task and dealing with the physics of the environment around it. Form follows function.

Robots have electrical components that power and control the machinery. For example, the robot with caterpillar tracks would need some kind of power to move the tracker treads. That power comes in the form of electricity, which will have to travel through a wire and originate from a battery, a basic electrical circuit.

Even petrol-powered machines that get their power mainly from petrol still require an electric current to start the combustion process which is why most petrol-powered machines like cars, have batteries. The electrical aspect of robots is used for movement (through motors), sensing (where electrical signals are used to measure things like heat, sound, position, and energy status), and operation (robots need some level of electrical energy supplied to their motors and sensors in order to activate and perform basic operations)

All robots contain some level of computer programming code. A program is how a robot decides when or how to do something. In the caterpillar track example, a robot that needs to move across a muddy road may have the correct mechanical construction and receive the correct amount of power from its battery, but would not be able to go anywhere without a program telling it to move.

Even petrol-powered machines that get their power mainly from petrol still require an electric current to start the combustion process which is why most petrol-powered machines like cars, have batteries. The electrical aspect of robots is used for movement (through motors), sensing (where electrical signals are used to measure things like heat, sound, position, and energy status), and operation (robots need some level of electrical energy supplied to their motors and sensors in order to activate and perform basic operations)

All robots contain some level of computer programming code. A program is how a robot decides when or how to do something. In the caterpillar track example, a robot that needs to move across a muddy road may have the correct mechanical construction and receive the correct amount of power from its battery, but would not be able to go anywhere without a program telling it to move.

Programs are the core essence of a robot, it could have excellent mechanical and electrical construction, but if its program is poorly structured, its performance will be very poor (or it may not perform at all). There are three different types of robotic programs: remote control, artificial intelligence, and hybrid. A robot with remote control programming has a preexisting set of commands that it will only perform if and when it receives a signal from a control source, typically a human being with remote control. It is perhaps more appropriate to view devices controlled primarily by human commands as falling in the discipline of automation rather than robotics.

Robots that use artificial intelligence interact with their environment on their own without a control source, and can determine reactions to objects and problems they encounter using their preexisting programming. A hybrid is a form of programming that incorporates both AI and RC functions in them.

Programs are the core essence of a robot, it could have excellent mechanical and electrical construction, but if its program is poorly structured, its performance will be very poor (or it may not perform at all). There are three different types of robotic programs: remote control, artificial intelligence, and hybrid. A robot with remote control programming has a preexisting set of commands that it will only perform if and when it receives a signal from a control source, typically a human being with remote control. It is perhaps more appropriate to view devices controlled primarily by human commands as falling in the discipline of automation rather than robotics.

Robots that use artificial intelligence interact with their environment on their own without a control source, and can determine reactions to objects and problems they encounter using their preexisting programming. A hybrid is a form of programming that incorporates both AI and RC functions in them.

Components

Power source

At present, mostly (lead–acid) batteries are used as a power source. Many different types of batteries can be used as a power source for robots. They range from lead–acid batteries, which are safe and have relatively long shelf lives but are rather heavy compared to silver–cadmium batteries which are much smaller in volume and are currently much more expensive. Designing a battery-powered robot needs to take into account factors such as safety, cycle lifetime, and weight.

Generators, often some type of internal combustion engine, can also be used. However, such designs are often mechanically complex and need fuel, require heat dissipation, and are relatively heavy. A tether connecting the robot to a power supply would remove the power supply from the robot entirely. This has the advantage of saving weight and space by moving all power generation and storage components elsewhere.

At present, mostly (lead–acid) batteries are used as a power source. Many different types of batteries can be used as a power source for robots. They range from lead–acid batteries, which are safe and have relatively long shelf lives but are rather heavy compared to silver–cadmium batteries which are much smaller in volume and are currently much more expensive. Designing a battery-powered robot needs to take into account factors such as safety, cycle lifetime, and weight.

Generators, often some type of internal combustion engine, can also be used. However, such designs are often mechanically complex and need fuel, require heat dissipation, and are relatively heavy. A tether connecting the robot to a power supply would remove the power supply from the robot entirely. This has the advantage of saving weight and space by moving all power generation and storage components elsewhere. Actuation

Actuators are the “muscles” of a robot, the parts which convert stored energy into movement. By far the most popular actuators are electric motors that rotate a wheel or gear, and linear actuators that control industrial robots in factories. There are some recent advances in alternative types of actuators, powered by electricity, chemicals, or compressed air.

Othes are; Electric motors, Linear actuators, Series elastic actuators, Air muscles, Wire muscles, Electroactive polymers, Piezo motors, and Elastic nanotubes.

Actuators are the “muscles” of a robot, the parts which convert stored energy into movement. By far the most popular actuators are electric motors that rotate a wheel or gear, and linear actuators that control industrial robots in factories. There are some recent advances in alternative types of actuators, powered by electricity, chemicals, or compressed air.

Othes are; Electric motors, Linear actuators, Series elastic actuators, Air muscles, Wire muscles, Electroactive polymers, Piezo motors, and Elastic nanotubes. Sensing

Sensors allow robots to receive information about a certain measurement of the environment, or internal components. This is essential for robots to perform their tasks, and act upon any changes in the environment to calculate the appropriate response. They are used for various forms of measurements, to give the robots warnings about safety or malfunctions, and to provide real-time information about the task it is performing.

Touch. Recent research has developed a tactile sensor array that mimics the mechanical properties and touch receptors of human fingertips. The sensor surrounded by conductive fluid contained by an elastomeric skin. When the artificial skin touches an object the fluid path around the electrodes is deformed, producing impedance changes that map the forces received from the object.

Vision. Computer vision is the science and technology of machines that see. Computer vision is concerned with the theory behind artificial systems that extract information from images.

In most, the computers are pre-programmed to solve a particular task, but methods based on learning are now becoming increasingly common.

Sensors allow robots to receive information about a certain measurement of the environment, or internal components. This is essential for robots to perform their tasks, and act upon any changes in the environment to calculate the appropriate response. They are used for various forms of measurements, to give the robots warnings about safety or malfunctions, and to provide real-time information about the task it is performing.

Touch. Recent research has developed a tactile sensor array that mimics the mechanical properties and touch receptors of human fingertips. The sensor surrounded by conductive fluid contained by an elastomeric skin. When the artificial skin touches an object the fluid path around the electrodes is deformed, producing impedance changes that map the forces received from the object.

Vision. Computer vision is the science and technology of machines that see. Computer vision is concerned with the theory behind artificial systems that extract information from images.

In most, the computers are pre-programmed to solve a particular task, but methods based on learning are now becoming increasingly common. Manipulation

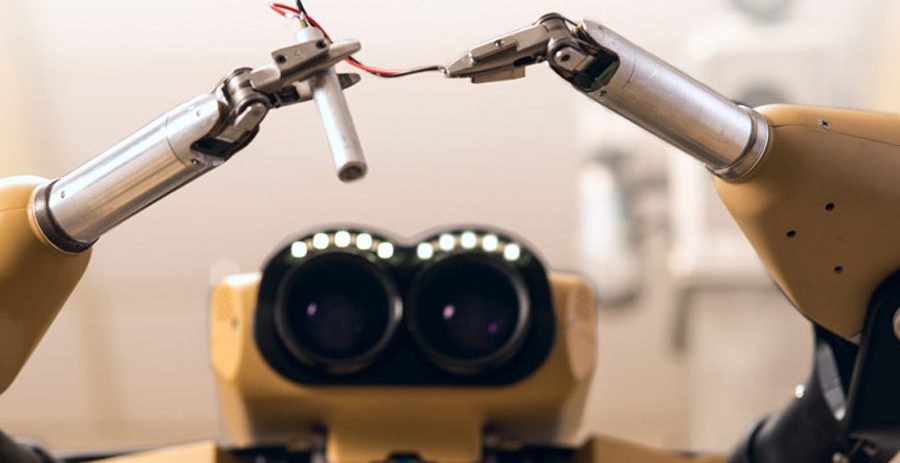

A definition of robotic manipulation has been provided by Matt Mason as: “manipulation refers to an agent’s control of its environment through selective contact”.

Robots need to manipulate objects; pick up, modify, destroy, or otherwise have an effect. Thus the functional end of a robot arm intended to make the effect (whether a hand, or tool) are often referred to as end effectors, while the “arm” is referred to as a manipulator.

Most robot arms have replaceable end-effectors, each allowing them to perform some small range of tasks. Some have a fixed manipulator that cannot be replaced, while a few have one very general-purpose manipulator, for example, a humanoid hand.

A definition of robotic manipulation has been provided by Matt Mason as: “manipulation refers to an agent’s control of its environment through selective contact”.

Robots need to manipulate objects; pick up, modify, destroy, or otherwise have an effect. Thus the functional end of a robot arm intended to make the effect (whether a hand, or tool) are often referred to as end effectors, while the “arm” is referred to as a manipulator.

Most robot arms have replaceable end-effectors, each allowing them to perform some small range of tasks. Some have a fixed manipulator that cannot be replaced, while a few have one very general-purpose manipulator, for example, a humanoid hand. Environmental interaction and navigation

Though a significant percentage of robots in commission today are either human controlled or operate in a static environment, there is an increasing interest in robots that can operate autonomously in a dynamic environment. These robots require some combination of navigation hardware and software in order to traverse their environment. In particular, unforeseen events (e.g. people and other obstacles that are not stationary) can cause problems or collisions.

Some highly advanced robots such as ASIMO and Meinü robot have particularly good robot navigation hardware and software. Also, self-controlled cars, Ernst Dickmanns’ driverless car, and the entries in the DARPA Grand Challenge, are capable of sensing the environment well and subsequently making navigational decisions based on this information, including by a swarm of autonomous robots. Most of these robots employ a GPS navigation device with waypoints, along with radar, sometimes combined with other sensory data such as lidar, video cameras, and inertial guidance systems for better navigation between waypoints.

Though a significant percentage of robots in commission today are either human controlled or operate in a static environment, there is an increasing interest in robots that can operate autonomously in a dynamic environment. These robots require some combination of navigation hardware and software in order to traverse their environment. In particular, unforeseen events (e.g. people and other obstacles that are not stationary) can cause problems or collisions.

Some highly advanced robots such as ASIMO and Meinü robot have particularly good robot navigation hardware and software. Also, self-controlled cars, Ernst Dickmanns’ driverless car, and the entries in the DARPA Grand Challenge, are capable of sensing the environment well and subsequently making navigational decisions based on this information, including by a swarm of autonomous robots. Most of these robots employ a GPS navigation device with waypoints, along with radar, sometimes combined with other sensory data such as lidar, video cameras, and inertial guidance systems for better navigation between waypoints. Human-robot interaction

The state of the art in sensory intelligence for robots will have to progress through several orders of magnitude if we want the robots working in our homes to go beyond vacuum-cleaning the floors. If robots are to work effectively in homes and other non-industrial environments, the way they are instructed to perform their jobs, and especially how they will be told to stop will be of critical importance. The people who interact with them may have little or no training in robotics, and so any interface will need to be extremely intuitive.

It will probably be a long time before robots interact as naturally as the fictional C-3PO, or Data of Star Trek, Next Generation. Even though the current state of robotics cannot meet the standards of these robots from science-fiction, robotic media characters (e.g., Wall-E, R2-D2) can elicit audience sympathies that increase people’s willingness to accept actual robots in the future. Acceptance of social robots is also likely to increase if people can meet a social robot under appropriate conditions.

The state of the art in sensory intelligence for robots will have to progress through several orders of magnitude if we want the robots working in our homes to go beyond vacuum-cleaning the floors. If robots are to work effectively in homes and other non-industrial environments, the way they are instructed to perform their jobs, and especially how they will be told to stop will be of critical importance. The people who interact with them may have little or no training in robotics, and so any interface will need to be extremely intuitive.

It will probably be a long time before robots interact as naturally as the fictional C-3PO, or Data of Star Trek, Next Generation. Even though the current state of robotics cannot meet the standards of these robots from science-fiction, robotic media characters (e.g., Wall-E, R2-D2) can elicit audience sympathies that increase people’s willingness to accept actual robots in the future. Acceptance of social robots is also likely to increase if people can meet a social robot under appropriate conditions.

Robotics

Applications

As more and more robots are designed for specific tasks, this method of classification becomes more relevant. For example, many robots are designed for assembly work, which may not be readily adaptable for other applications. They are termed “assembly robots”. For seam welding, some suppliers provide complete welding systems with the robot i.e. the welding equipment along with other material handling facilities like turntables, etc. as an integrated unit.

Such an integrated robotic system is called a “welding robot” even though its discrete manipulator unit could be adapted to a variety of tasks. Some robots are specifically designed for heavy load manipulation, and are labeled as “heavy-duty robots”.

As more and more robots are designed for specific tasks, this method of classification becomes more relevant. For example, many robots are designed for assembly work, which may not be readily adaptable for other applications. They are termed “assembly robots”. For seam welding, some suppliers provide complete welding systems with the robot i.e. the welding equipment along with other material handling facilities like turntables, etc. as an integrated unit.

Such an integrated robotic system is called a “welding robot” even though its discrete manipulator unit could be adapted to a variety of tasks. Some robots are specifically designed for heavy load manipulation, and are labeled as “heavy-duty robots”.

Current and potential applications include:

Current and potential applications include:

- Military robots.

- Industrial robots. Robots are increasingly used in manufacturing (since the 1960s). According to the Robotic Industries Association US data, in 2016 the automotive industry was the main customer of industrial robots with 52% of total sales. In the auto industry, they can amount for more than half of the “labor”. There are even “lights off” factories such as an IBM keyboard manufacturing factory in Texas that was fully automated as early as 2003.

- Cobots (collaborative robots).

- Construction robots. Construction robots can be separated into three types: traditional robots, robotic arm, and robotic exoskeleton.

- Agricultural robots (AgRobots). The use of robots in agriculture is closely linked to the concept of AI-assisted precision agriculture and drone usage. 1996-1998 research also proved that robots can perform a herding task.

- Medical robots of various types (such as da Vinci Surgical System and Hospi).

- Robot-assisted surgery designed and used in clinics.

- Kitchen automation. Commercial examples of kitchen automation are Flippy (burgers), Zume Pizza (pizza), Cafe X (coffee), Makr Shakr (cocktails), Frobot (frozen yogurts), Sally (salads), salad or food bowl robots manufactured by Dexai (a Draper Laboratory spinoff, operating on military bases), and integrated food bowl assembly systems manufactured by Spyce Kitchen (acquired by Sweetgreen) and Silicon Valley startup Hyphen. Home examples are Rotimatic (flatbreads baking) and Boris (dishwasher loading).

- Robot combat for sport – hobby or sports event where two or more robots fight in an arena to disable each other. This has developed from a hobby in the 1990s to several TV series worldwide.

- Cleanup of contaminated areas, such as toxic waste or nuclear facilities.

- High temperature crucibles allow robotic systems to automate sample analysis.

- Domestic robots.

- Nanorobots.

- Swarm robotics.

- Autonomous drones.

- Sports field line marking.

- Educational robotics. Robots such as LEGO® Mindstorms are used to teach coding, mathematics, and creative skills.